Saving up to 20% diesel consumption by using Machine Learning in hybrid systems

SUMMARY

By developing a set of machine learning models and optimization algorithms, we have achieved savings of hundreds of thousands liters of diesel each year, without compromising the life expectancy of the system components. We’ve also provided a system of “digital twins” which allows to dimension new or existing systems as well as to detect unexpected behaviors of deployed systems.

These same techniques can be applied to a wide range of use cases like energy cost reductions, taking energy from the grid when price is lower, monitor and dimension hybrid systems, forecast energy demand to adjust energy production.

DESCRIPTION OF THE USE CASE

Our customer operates hundreds of cell phone towers over the world. Most of these towers are in rural areas without access to the electric grid, so their energy supply is obtained from photovoltaic arrays and a diesel generator set.

These hybrid systems get support from battery arrays to cover the time periods where generator set is off and solar production is lower than the tower consumption.

We were challenged to optimize the usage of the diesel generator set by automatically adjusting the schedules for the next 24 hours.

OUR APPROACH

We’ve developed a set of machine learning models that are trained using multiple data sources like consumption historical data, energy production historical data or weather forecast data.

These models can predict expected energy consumption from the cell towers, solar energy production and energy loss from the battery usage for the next 24 hours.

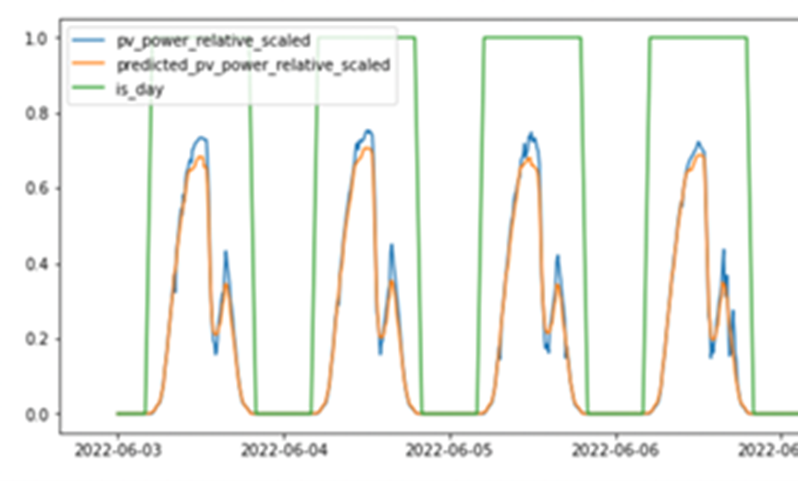

Solar production forecast vs historic.

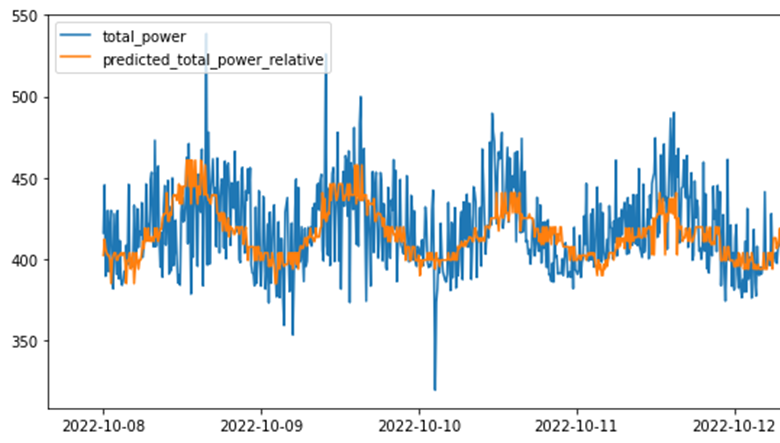

Energy demand forecast vs historic.

Using the forecasted data, we’ve developed two optimization algorithms:

The first one outputs the ideal battery levels when the generator set should be started and stopped for the next day to automatically configure the schedule.

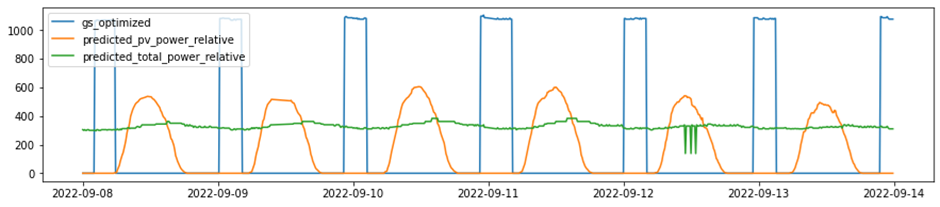

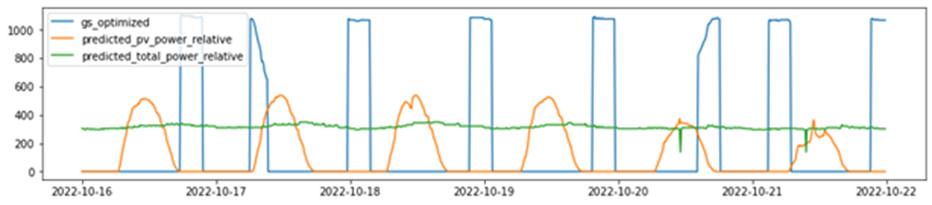

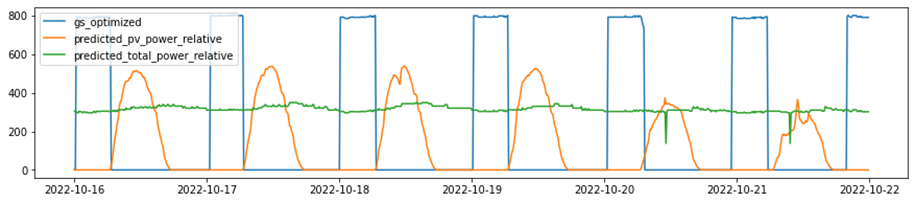

Forecasted optimization.

The second algorithm provides a powerful decision support tool which allows our customer to find the optimal battery charging speeds, so they can choose between more fuel-saving oriented setups or lower maintenance setups.

Optimized to minimize the time generator set is ON (Fuel savings).

Optimized to minimize the number of times generator set is started

(Maintenance savings).

Additionally, we’ve developed a system that acts as a “digital twin” to support our customer in dimensioning new or existing systems. This system forecast system energy consumption, energy production, generator set usage and fuel consumption given hypothetical hardware and configuration setups:

- what if … we add 2 additional solar panels

- what if … we lose one battery in the array

- what if … tower consumption is increased by 50%

These “digital twins” can be compared with the real systems to monitor unexpected behaviors alerting our customer upon system failures or anomalies.

Energy production and demand monitoring

THE RESULTS

The system allows our customer to tune the optimization for each tower towards fuel savings vs maintenance costs savings, this flexibility outputs infinite possible outcomes ranging from:

More than 20% savings in fuel consumption with less than 4,5% increase in generator set starts using setups oriented to minimize the time that generator set is on

TO

Decrease greater than 20% of the generator set starts and slower battery charges with an increase of less than 8,2% fuel consumption for setups aggressively oriented to reduce maintenance costs.

Using the decision support algorithm, our customer is selecting balanced setups that are providing more than 15% average fuel savings while not increasing the generator set starts. This translates into hundreds of thousands liters of diesel saved each year without compromising the generator set and battery life expectancy. As additional outcome, our customer benefits from a new powerful decision support system that helps them in dimensioning and monitoring tasks using the “digital twins” system.

David Marcos

Data Analytics Business Manager, Innovery